83CG

Τhe best value for money for your magnesite bonded abrasive wheels

Τhe best value for money for your magnesite bonded abrasive wheels

83CG is a calcined magnesium oxide, produced under closely controlled conditions to give a finely divided white powder with controlled and uniform reactivity.

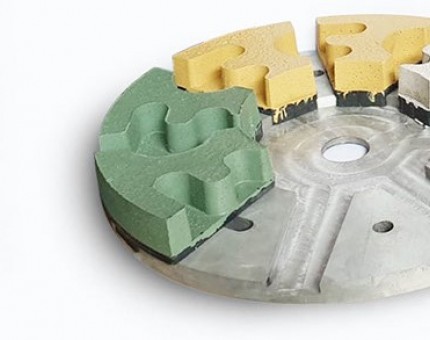

83CG is manufactured for use in the production of magnesium oxychloride (SOREL cement) abrasive stones│grinding & polishing wheels. It reacts with magnesium chloride to form an eco-friendly cement, capable of bonding a wide variety of minerals and organic aggregates.

Main Uses & Advantages

Its unique properties such as whiteness, proper MgO availability, consistent particle size and controlled reactivity (able to produce mortars with adjustable setting properties) renders 83CG the best value for money for your grinding and polishing needs.

83CG is produced in two main versions, adjusted for seasonal variations in temperatures.

83CG has a time-tested history in the following main uses:

- The marble, granite and mosaic processing industries

- The ceramic tile industry (gres porcelanato)

- The manufacture of special millstones for rice peeling where the ecological properties of MOC cement are highly appreciated

Packaging & Storage

83CG is available in powder form & packed: In big bags, with or without bottom spout. In 25 kg paper bags on pallets, wrapped in shrink film.

83CG has a shelf life of 12 months provided that the product is stored in a clean dry storage area and is protected from moisture with PE-foil. Magnesium oxide absorbs moisture from the air and forms lumps. Always re-seal partly used pallets and single bags with PE-foil.

| MgO Content (Loss free): | typ. 86.00% |

Order now

OR CONTACT US FOR ANY INFORMATION

Email: info@grecianmagnesite.gr

Abrasives - Polishing stones - Rice Milling

A principal application of MOC cement - magnesium oxychloride cement - (addition of caustic calcined magnesia to MgCl2 solutions) is in the manufacture of abrasive stones and grinding wheels.