88 C/SK

88 C/SK │ Τhe premium product for the highest quality magnesite bonded abrasives

88 C/SK │ Τhe premium product for the highest quality magnesite bonded abrasives

88 C/SK is a moderately reactive calcined magnesium oxide, produced under closely controlled conditions to give a finely divided white powder, with low iron content and controlled - uniform reactivity.

88 C/SK is manufactured for use in the production of high quality - maximum performance - magnesium oxychloride (SOREL) cement, abrasive stones│grinding & polishing wheels. It reacts with magnesium chloride to form an eco-friendly cement, capable of bonding a wide variety of minerals and organic aggregates.

Main Uses & Advantages

The unique properties of 88 C/SK such as its whiteness, high MgO availability, low free lime, consistent particle size and controlled reactivity (producing mortars with adjustable setting properties) renders 88 C/SK the very best choice for your grinding & polishing needs │ For wheels with high production efficiency and low production cost.

88 C/SK is produced in two main versions, adjusted for seasonal variations in temperatures.

88 C/SK has a time-tested history in the following abrasive applications:

- The manufacture of special millstones for rice peeling where the ecological properties of MOC cement are highly appreciated

- The marble, granite and mosaic processing industries

- The ceramic tile industry (gres porcelanato)

- The stainless steel cutlery processing (household objects, eg. knives)

88 C/SK is also successfully used in secondary backfilling Sorel cement formulations (e.g., filling of boreholes and openings) in active and old mines used as waste repositories offering controlled setting times, mechanical strength and expansion.

88 C/SK is also suitable for bridging agents, Sorel cement-based formulations in drill-in or servicing fluids and other special non-permanent sealing cements in oil-field operations.

Packaging & Storage

88 C/SK is available in powder form: In big bags, with or without bottom spout. In 25 kg paper bags on pallets, wrapped in shrink film.

88 C/SK has a shelf life of 12 months provided that the product is stored in a clean dry storage area and is protected from moisture with PE-foil. Magnesium oxide absorbs moisture from the air and forms lumps. Always re-seal partly used pallets and single bags with PE-foil.

| MgO Content (Loss free): | typ. 91.00% |

| Fe2O3: | typ. 0,15% |

| Free Lime: | < 0,60% |

Order now

OR CONTACT US FOR ANY INFORMATION

Email: info@grecianmagnesite.gr

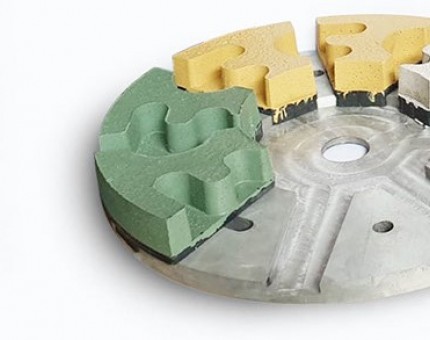

Abrasives - Polishing stones - Rice Milling

A principal application of MOC cement - magnesium oxychloride cement - (addition of caustic calcined magnesia to MgCl2 solutions) is in the manufacture of abrasive stones and grinding wheels.

Backfilling Cement

Caustic calcined magnesium oxide is also used in sorel cement formulations that serve as secondary backfilling cements (e.g., filling of boreholes and openings) in active and old mines used as waste repositories.

The magnesium oxide product must fulfill several characteristics that will guarantee appropriate cement setting time, mechanical strength and expansion.

Drilling Cements

In some cases, special, non-permanent sealing cements are required to establish a seal and subsequently remove it by dissolving the cement with common oil-field acids, something that cannot be accomplished with conventional cements. Sorel cement formulations based on caustic calcined MgO grades can be used in such cases.