93C BL

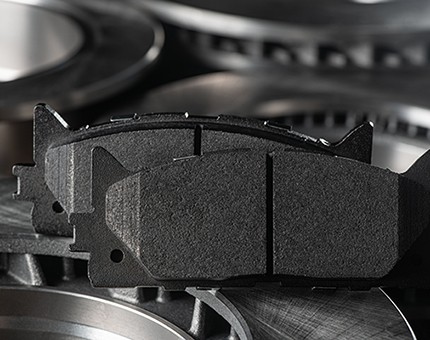

93C BL ǀ For consistent & high quality brake linings and brake pads

93C BL ǀ For consistent & high quality brake linings and brake pads

93C BL is a relatively high purity calcined magnesium oxide grade, produced under closely controlled conditions to give an accurately sized white powder, with consistent (medium) reactivity & density.

93C BL has been especially developed for the friction materials industry.

Main Uses & Advantages

93C BL is being effectively used by several leading manufacturers of friction materials all over the world. It is typically added in brake pad and linings formulations at around 2-5 % to adjust the friction coefficient to desirable values. Added benefits are the reduction of wear on metal, the enhancement of heat transfer & fade resistance and the suppression of low frequency noise during breaking.

The main advantages of 93C BL are its carefully controlled chemical composition, reactivity and grain size to ensure appropriate and consistent hardness and powder bulk density, guaranteeing stable specific consumption and void volume control in the lining. Moreover, its low moisture content ensures problem-free handling and minimized gas emissions during curing.

As producers of magnesium oxide, with flexible processing facilities, we offer our global customers additional advantages; the ability to produce and deliver, just in time, small batches (even 1mt) all over the world and most importantly, supply security & price stability!

Packaging & Storage

93C BL is available in powder form: In big bags, with or without bottom spout. In 25kg paper bags on pallets, covered with shrink film.

93C BL has a shelf life of 12 months provided that the product is stored in a clean dry storage area under proper conditions. Magnesium oxide absorbs moisture from the air and forms lumps. Always re-seal partly used bags.

| MgO Content (Loss Free): | typ. 93,5% |

| Sizing: |

available at -63 μm, 99% |

Order now

OR CONTACT US FOR ANY INFORMATION

Email: info@grecianmagnesite.gr

Friction Materials

Magnesium oxide is an important component in friction material formulations, typically added to adjust the friction coefficient at desirable values in brake pads and brake linings. Moreover, its intermediate hardness imparts sufficiently low wear on metal while adequately conducting heat from the friction contact surfaces.