QUALITY CONTROL

Rigorous testing procedures and statistical process control are employed at every stage of the production, from the mining of the mineral deposit through the dispatching of the final product. Grecian Magnesite’s products are supplied to stringent specifications. All products are fully verified for key properties to ensure that they conform to specification.

A certificate of analysis is supplied with every shipment. It indicates the key parameters requested for the application that the product is destined for. Chemical analysis and particle size distribution are the main parameters requested.

The use of raw materials from our own mines gives us the advantage of working with materials of stable chemical composition and physical properties, whose performance has been tested over and over again. This results in products of superior as well as consistent quality.

Grecian Magnesite’s Quality Control Laboratory is located in Yerakini nearby the main production facilities, in order to support the company’s production departments (i.e. mining, beneficiation, calcination and final processing).

Its main task is the chemical analysis of materials produced in all stages of production. Another important task is the evaluation of the physicochemical properties of our products, important because these properties determine their performance in downstream uses.

Analyses and measurements are performed according to European and International standards (i.e. EN, ASTM, ISO and PRE).

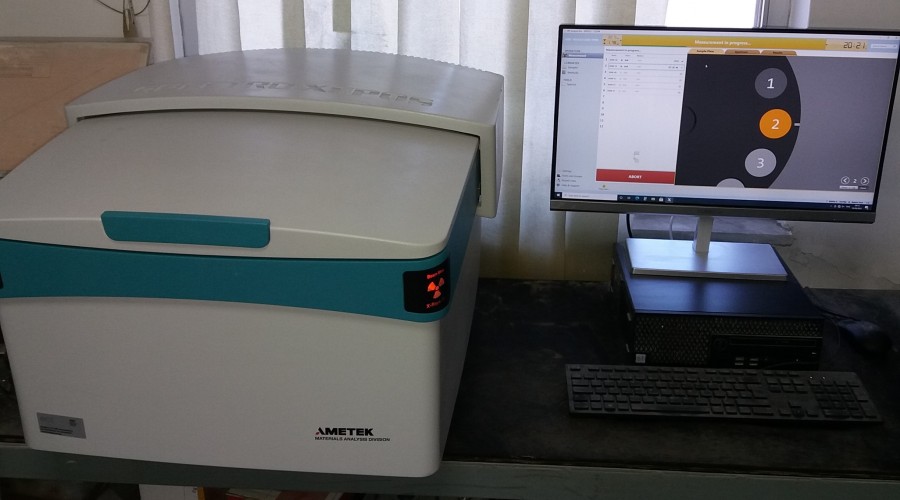

A summary of the available equipment and analyses conducted follows.

Sample preparation:

Jaw crusher, disc mills, sieves and sieving machines for sample preparation and grain size analysis of “coarse” materials.

Chemical analysis:

- X-Ray Fluorescence (SPECTRO XEPOS C).

- C/S ANALYZER CS800 ELTRA.

- UV-VIS SPECTROMETER HITACHI 181.

- ATOMIC ABS SPECTROSCOPY THERMOELEMENTAL SOLAR S.

- Wet Chemical Analysis.

Physicochemical properties:

- Acid reactivity, alkalinity and pH.

- Bioavailability, absorption and setting time of caustic magnesia.

- Bulk and loose density for granular materials.

- Loose and tapped density for powder materials.

- Hydration resistance of dead burned magnesia.

- Powders grain size distribution via:

- MALVERN MASTERSIZER 3000E,

- Alpine air jet sieving machine (a200ls),

- Α complete series of test sieves.

Other:

Analytical balances, thermal furnaces, pH meters, etc.

Finally, apart from the analysis of Magnesia products, the lab is able to also conduct the main characterization tests for:

- Τhe aggregate production department (grain size, equivalent sand, etc).

- Solid and liquid fuels (calorific value with the automatic adiabatic bomb calorimeter GALENKAMP AUTOBOMB).

Further tests and measurements of the mineralogical, microstructure and physicochemical properties of our products are conducted in our R&D center.